EXCLUSIVE: The Coming Revolution in Electric Football Uniforms

A new product launch could be a game-changer — literally.

Like a lot of people — including, I’m sure, many of you who are reading this — I grew up playing Electric Football, the game with the little plastic figurines that move around a vibrating gridiron. I got my set as a Christmas gift when I was 10 years old and spent many an hour playing down in our basement (where I learned, like many before me, that getting the figurines to go where I wanted them to go — to say nothing of completing a pass or kicking a field goal — was a lot trickier in real life than it appeared in a TV commercial).

Naturally, I was fascinated by the little figurines’ uniforms, which were painted on by what I imagined to be an army of impossibly small artists wielding tiny brushes. The uniforms weren’t perfect — stripes weren’t always quite straight, colors occasionally bled into each other, and helmet logos were usually just an indistinct smudge — but you could always tell the Bills from the Cowboys, or the Steelers from the 49ers, or whatever. For a young uni-obsessed fan, just the attempt to get all the details right at such a miniature scale was exciting, even if the execution wasn’t quite flawless.

Electric Football is pretty much the definition of analog, so you might assume it was rendered obsolete years ago by video games. But it’s still in production, thanks to a combination of nostalgic older hobbyists and new generations of fans who’ve kept the game alive. Electric Football probably won’t be challenging Madden for football game supremacy anytime soon, but the people who are into it are really into it. YouTube is overflowing with Electric Football videos, plus there are fan websites, tournaments, leagues, conventions, and apparel. Serious players — or coaches, as they often prefer to be called — will even shell out hundreds of dollars to have their figurines custom-painted with uniforms that go beyond the usual stock designs. It’s a vibrant subculture that has become, in its own way, an American institution.

Electric Football is still manufactured, as always, by Tudor Games. The company is run these days by Doug Strohm, a former tech guy and game designer who acquired Tudor in 2012 and takes his stewardship of Electric Football’s heritage seriously. He’s now come up with an innovation that he thinks will completely revolutionize the game — and it’s all about the uniforms.

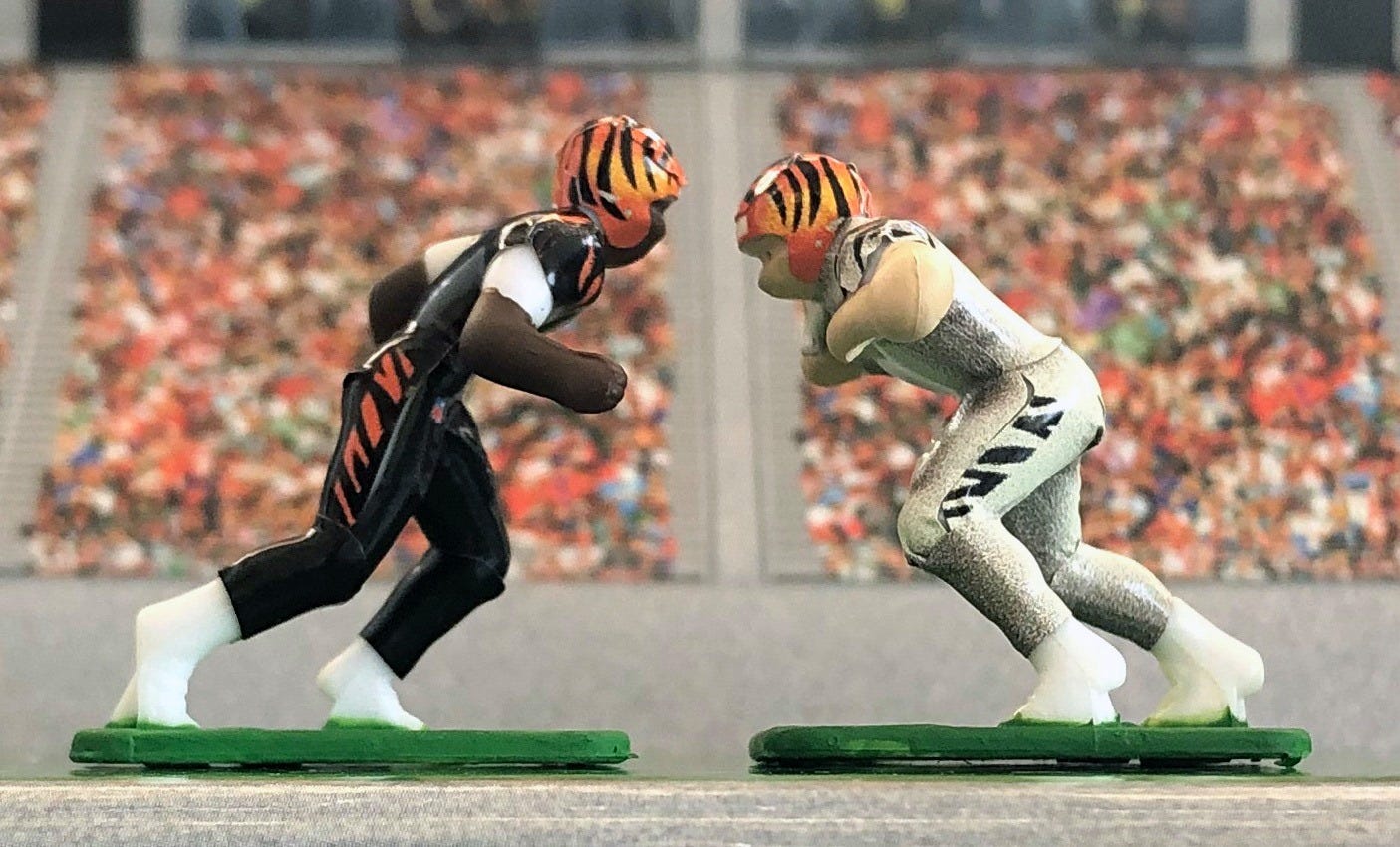

Here’s the deal: Tudor will soon begin selling a series of 3" by 3" decal sheets called Uni-Forms. Each sheet will feature a series of die-cut, adhesive-backed films. When the tiny decals are applied to a blank player figurine in the proper sequence, the result is a full NFL uniform with crisp, accurate graphics, right down to the league logo on the jersey chest and right pant leg.

The decals include shading and shadows to simulate a real-life appearance. In an additional touch of realism, the helmet decals even include a representation of the familiar flex-panel cutout on the popular Riddell SpeedFlex helmet.

For each player there are nine decals — two for the jersey (front and back, the latter of which also includes any striping or logos on the sleeves); three for the pants (front left, front right, and back); two for the socks (left and right); and two for the helmet (center and sides) — and that’s before you get to the the front and back jersey numbers, the TV numbers on the sleeves or shoulders, and, for some teams, the helmet numbers. Each sheet has enough decals for two or three players, and each set of sheets includes all the numerals needed for the various uni numbers.

I wanted to learn more about all of this, so I recently spoke with Strohm. Here's a transcript of our chat (edited for length and clarity):

Uni Watch: Who is the typical electric football fan these days? Is it a middle-aged hobbyist who grew up playing the game, or is it a kid discovering it for the first time?

Doug Strohm: The strongest demographic is probably ages 40 to 65. But we also get a lot of kids — it’s still a very, very popular Christmas gift.

UW: When I was growing up, the players were all hand-painted. Was that all done overseas?

DS: For a while they were done in Haiti. You can tell those because they all had black shoes. Those are regarded as some of the best from the hand-painted era, and they’re highly sought after as collector’s items. Unfortunately, the Haitian factory burned down, so then the painting moved to Hong Kong, I think, and then China. For a while the regular order of business for Tudor in those days was to find a factory in China, and then when the factory found out how difficult it was to paint the players, they wouldn’t renew the contract. So then they would go find another factory that would take the contract. And, you know, that’s not really a recipe for consistency and quality and all those kinds of things.

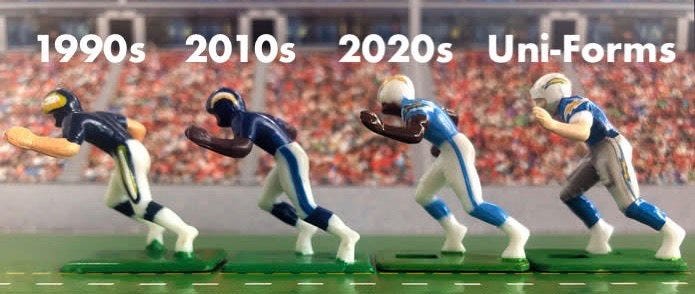

UW: Have they stayed hand-painted all these years, or has the production process changed?

DS: It has changed. A lot of people in this hobby paint their own players, so we wanted to come out with waterslide decals, like the old model kits. So that way, you paint your player and then you slide the waterslide decals onto the figure. Then you use a product called Solvaset, which makes those decals more pliable and allows them to lay over a curved surface. And then when you’re done, you put a gloss coat over that. So we thought, because we’re going to do the waterslide decals as a product anyway, we’ll send the decals to China and have China paint and decal the figures, just like someone would be doing in the U.S., but they could do it a lot faster in China.

What we found out is that the cost to have them do all the details and the figures would have been astronomical and our teams would have to be selling for $30 to $35 each, instead of $14.95. Also, sometimes they’d apply the decals incorrectly — we’d get Seahawks figures with the Seahawks logo wrapped around the helmet upside-down, that type of thing. So we had quality control issues with that.

Then I looked into a new process, which involves stamping the figures with a multicolor pad. And that process produced some of the best logos that we’ve ever had. But it could only do the figure’s helmet logo, helmet stripes, and shoulder decoration — any other part of the figure would have been prohibitively expensive. So you can see, we’ve had a lot of challenges with the uniforms, and that’s why we’re so excited to be able to bring this new product to market, which changes everything for us.

UW: So you’re referring to Uni-Forms. Tell me about that, and why it’s such a game-changer.

DS: The way we’ve been working in the past, it’s a four-month lead time to get the players made, plus three weeks for them to ship from China. So every summer I have to be a Las Vegas oddsmaker: Which teams are going to be good? What free agent signings have happened? You know, what are the tea leaves? The teams that are strong traditionally, they always sell for us. But the teams that aren’t always so good, there’s a big difference. Here’s an example: When Tom Brady went to the Bucs, I had just ordered a bunch of Patriots sets. The minimum order is 1,000 units, and I think I bought 1,250. Brady goes to the Bucs and all of a sudden, I can’t sell any Patriots. Meanwhile, all my Bucs sell out almost immediately. And if I want to restock, I’m looking at four more months.

Also, you have all these alternate and Color Rush uniforms, plus I always have some people asking for this throwback, other people asking for that throwback. And you just can’t please anybody because the nature of the production process means that you can really only do one home and one away version, per team, times 32. So that’s 64 sets at multiple thousands of dollars per run.

UW: You’re saying you couldn’t do an alternate or throwback or Color Rush or whatever, because of cash flow and having that much capital tied up in every last uniform combination?

DS: Right. You know, a lot of our fans and people who come to our website don’t realize that the breadth of uniform options that we offer for certain teams is a result of unsold inventory. So when I say everybody wants this or that, you know, that’s a small sample size of who speaks out, but gosh, it’s just frustrating because I can’t satisfy the customer, which is disheartening. And that’s why I’ve been working for the last two or three years to find a new way to decorate the players. Could we use 3D printing? Could we use shrink tubing in some way — some sort of a plastic material that we add and shrink onto the figures? You know, how can we do this?

And it wasn’t until I cut myself in the warehouse last Dec. 8 that I found the answer. I opened the first aid kit, took out a Band-Aid, and it was clear. And I thought, “Oh, that’s cool — Band-Aids have come a long way, they’re clear now.” And then I was like, wait a minute, could this be a way to wrap our little football figures with some sort of a printable film? And that’s where Uni-Forms came from.

We first tested it with tattoo film — you know, when you get a tattoo, they put that clear, breathable plastic over the new ink. We tried printing on that, because it was nice and thin, but it deformed when you pulled on it. So then we started looking at film after film after film, until we found some stuff that we really liked. And then it was, okay, what do the patterns need to look like? You know, how many pieces need to go on each figure, and what’s the best way to conform around all of these curves?

And it really is a game-changer for us. It changes our inventory model, because I’m not going to have obsolete products sitting on the shelf. I can print the decals locally on demand as I need them.

UW: So now you can have the figurines made as blanks, and then when somebody says they want the Buccaneers, or the Cowboys, or whatever, they’re not asking for the player — they’re really just asking for the decals, which are much easier for you to make and don’t require the four-month lead time and all of that.

DS: Exactly. We have a printer who’s five, ten miles away, who’s going to do the majority of these for us, but we also want to have the responsiveness to start to be able to do these ourselves, on-site. So if somebody says, “Hey, I want the fifth alternate Oregon Ducks uniform,” we can say yes. It all comes back to saying yes to our customers, instead of “No, I’m sorry, that’s all we have. No, we don’t have anything more detailed than this."

What this represents to us is basically a catalog of the history of football. That’s what we want this to be. We want to do almost every NFL uniform that’s ever existed, so we’re working with the guys at the Gridiron Uniform Database website, which chronicles football uniform history, to get the designs right. And then we’ll also have Color Rush, alternate, classic, and throwback uniforms as well.

UW: Do you think your average fan has the patience and the dexterity to futz with all these little decals?

DS: Yeah, you know, that’s a risk of this whole thing. Are people going to want to do this? But from what we’ve seen from our beta testers, the more often you do it, the better you get at it. And, you know, we were just honestly just blown away by the feeling you get when you’re done with a figure — like, “This is my figure, I made him.” So we think that will appeal to people.

We know the electric football community is very passionate, so when you make a change like this, you’re going to make some people happy, and you’re probably going to make some other people unhappy. But for the reasons I’ve talked about earlier, as far as the health of the company and inventory and being able to say yes, and all that stuff, there’s just no reason why we would go back to the old model, so we are moving forward with this. And you know, earlier this year, I had some decisions to make — I needed to order probably about eight to 10 teams of figures. And I decided not to order them. We’re going with this new way instead.

UW: A minute ago you mentioned saying yes to an Oregon Ducks request. So are you getting the licenses together to offer college uniforms as well?

DS: Yes. Before, we didn’t really have the capital to go into the college market. I mean, I can’t just order 100 Ohio State players, go and get the Ohio State license, and make that a winning business proposition. I’d have to buy 1,000, and trust that they’re gonna sell. That may seem like a no-brainer — I get plenty of people who call and say, “Yeah, if you do that, I’ll buy one.” That’s great, but this is a business, it’s got to be at a scale that makes sense. And we believe that by using Uni-Forms to do that, we can make those minimums go away.

We are about to sign a contract to get the Ohio State license, and we also have an application for another few schools with the Collegiate Licensing Company, which handles most, if not all, of the college programs. That way, we can add 10, 20 teams very quickly. And that’s what we plan to do for this season. So Uni-Forms, in addition to improving our NFL product, also gives us the opportunity to add college to the mix.

UW: What about nameplates?

DS: We actually have an offer on the table with the NFL Players Association to license those as well, so you’d be able to have your favorite player’s name on the back of the jersey. And what’s exciting to the Players Association is that we don’t want to do just the top players — we want to do the entire roster. So that’s something we’re working on.

UW: What if someone wants to design their own Uni-Forms, based on, you know, their fantasy team, or just something they dreamed up? Do you plan to offer that?

DS: Yeah, at some point, but probably not this year.

———

Strohm expects Uni-Forms to be available in September or October. But Tudor is also taking pre-orders, at a discounted price, via an IndieGoGo campaign.

It all sounds good, right? And Tudor has created an excellent instructional video showing how all the decals are applied:

But is applying the decals really as simple as it seems in the video? I wanted to find out for myself, so Strohm sent me a bunch of blank figurines and a set of Los Angeles Chargers decals. I recently spent an afternoon trying them out.

For my first attempt, I decided to outfit a running back figurine. Now, I'm not super-crafts-y, but I like to think of myself as reasonably nimble-fingered — I can easily thread a needle and sew a button, for example. But working with the tiny decals was challenging.

I did my best to position everything correctly and smooth out all the wrinkles and creases, but I felt like the finished product left a lot of room for improvement.

As you can see in the photos, I decided to make things a bit simpler for myself by giving the player a single-digit uni number (hey, NFL running backs are allowed to wear those now!). Speaking of numbers: The good news is that the Chargers’ jerseys don’t have TV numbers, so I didn’t have to apply those to the shoulders. The bad news is that their helmets have TV numbers, and the decal sheets included teeny-tiny numerals for this purpose. I made an executive decision not to attempt those, since I was fairly certain it would not end well.

Next I tried a “sprinter” — the same figure shown in the instructional video. Once again, I went with a single-digit uni number. Also, since the figurines’ heads are white and the top of the Chargers’ helmet is just plain white, I decided to skip the top-helmet decal, since it didn’t add anything to the uni design. (I figured it was okay if this guy wasn't wearing a SpeedFlex helmet.) Working with the decals was a bit easier this time, and the results were a bit better.

I eventually used the Uni-Forms on 10 players. Each time, the process felt more familiar. That’s not to say it was easy — it’s delicate, painstaking work — but I definitely felt more comfortable with it as I went along, just like Strohm said about his beta testers, and that showed in the results.

All in all, the Uni-Forms product seems promising. It’s too soon to say what it will mean for the future of Electric Football, but the expansion of uni options seems like an obvious plus, as does the prospect of fans having a more hands-on experience with the game's uniforms. Most of all, Uni-Forms should get people thinking and talking a lot more about uniforms, and that's something I can always get behind.

• • • • •

Update: In last week’s piece about left- and right-facing team logos, I speculated that so many NFL team logos face to the right because NFL helmets are typically depicted facing to the right, and that the right-facing helmet orientation may be due to the Steelers wearing a logo on only one side of their helmet. But reader Doug Brei has suggested that there might be another reason for the right-facing helmet default.

Brei notes that NFL pennants — which seem quaint now but were very popular back in the 1960s and ’70s — used to routinely show a team’s helmet (while pennants for teams in other sports usually just showed a team logo). And since pennants taper from left to right, there was little choice but to show the helmet facing rightward:

This may have driven the near-universal depiction of helmets facing to the right, which in turn may have driven the tendency of NFL teams to create right-facing logos. Interesting analysis!

———

Paul Lukas has been writing about uniforms for over 20 years. If you like his Bulletin articles, you’ll probably like his daily Uni Watch Blog, plus you can follow him on Twitter and Facebook, and check out his podcast. Want to learn about his Uni Watch Membership Program, check out his Uni Watch merchandise, or just ask him a question? Contact him here.